Dry benchmark control

(1) The start of the drying room. Close the inlet and exhaust ducts; start the fans. For a reversible circulation drying room with multiple fans, start the fans one by one. Do not start several fans at the same time to avoid overloading the circuit; open the valve of the bypass pipe of the steam trap and open it slowly. Heater, to make the heating system heat up slowly and discharge the air, water and rust in the piping system at the same time, when a large amount of steam is ejected from the bypass pipe, then close the valve of the bypass pipe and open the steam trap valve to make the steam trap work normally .When the indoor dry bulb temperature rises to 40-50 degrees Celsius, it must be kept warm for 0.5h to preheat the inner wall of the drying room and the wood surface, and then gradually open the heater valve and spray steam properly to make the dry and wet bulb temperatures rise simultaneously To the state of the medium required for preheating. When entering the drying stage after the treatment, the inlet and exhaust channels must be opened, and then operate according to the process requirements.

(2) Preheat sawn timber. After the wood drying room is started, the wood is preheated first. The purpose of preheating is to heat the wood and make the wood heat through, keep the direction of the moisture gradient and the temperature gradient consistent, and eliminate the growth stress of the wood. It also has the effect of eliminating surface stress for semi-dry wood and air-dry wood. Wood and wet wood, preheating can make the wood with high moisture content evaporate part of the water, so that the moisture content tends to be consistent. At the same time, preheating can also reduce the saturation point of dead fibers and the viscosity of water, expand the capillaries on the wood surface, and increase the gradient of water movement on the wood surface.

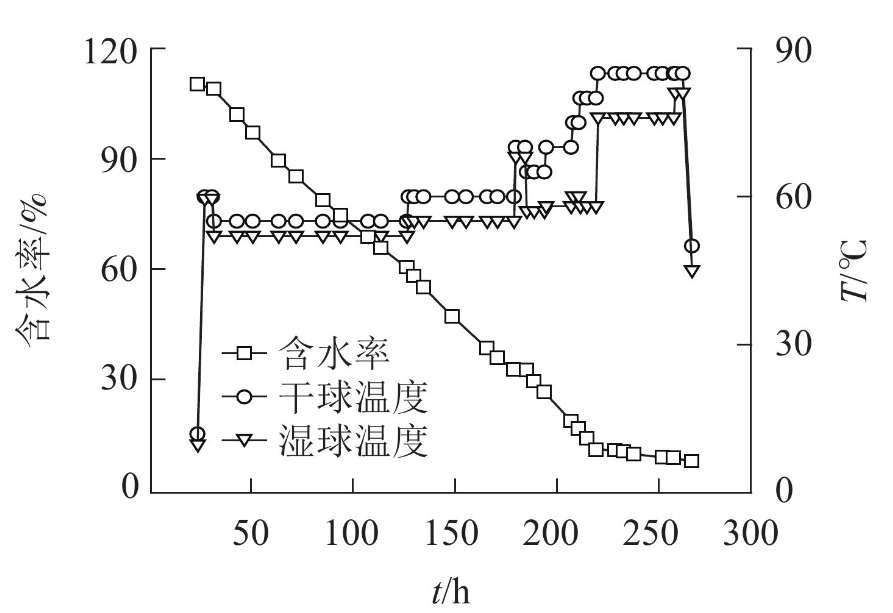

(3) Adjust the temperature and humidity of the drying room. After the wood has been preheated, it is already in the best state of drying, so it can be transferred to the drying standard to enter the drying stage. During the drying process, the adjustment of the drying medium parameters is carried out strictly according to the drying standard. When doing temperature conversion, it is not allowed to sharply increase the temperature and decrease the humidity. Otherwise, the water on the surface of the wood will evaporate strongly, causing the surface water to evaporate too fast, and the surface will easily crack.

(4) Mid-term treatment. During the drying process of wood, since the evaporation rate of moisture on the surface of the wood is about 10 times greater than the velocity of moisture movement inside the wood, the moisture content on the surface of the wood first decreases to the fiber saturation point and begins to shrink. The moisture content is still well above the fiber saturation point, and the harder the dry base, the more prominent this phenomenon and the more likely the wood will crack. Therefore, during the test drive drying operation, it is necessary to carry out mid-term treatment in a timely manner according to the drying state.

(5) End processing. When the sawn timber is dried to the final moisture content, the final treatment is carried out. The purpose of the final treatment: to eliminate the uneven distribution of moisture content on the cross-section of the wood and to eliminate the residual stress. Sawn timber requiring dry quality grades 1, 2 and 3 must be finished.

Our main products cover Conventional Wood Drying Kilns,Track Type Veneer Drying Kilns,Heat Pump Drying Kilns,food drying chambers, heat treatment kiln and so on.If you are interested, welcome to contact me.