Track Veneer Drying Kiln With Automatic Control System

- Chiqin

- China

- One month after receiving the money

- 30 sets per month

Our company develops a track-type efficient veneer kiln successfully which obtains the national patent combining wood drying characteristic after many years reseach and experiment.The drying kilns are hot selling in wood processing industry at home and abroad.

The veneer drying kiln has the advantages of high efficient energy-saving,short drying cycle,good drying quality and low drying cost.The veneer drying kiln is widely used in plywood industry.

Track Veneer Drying Kiln With Automatic Control System

The features of efficient track veneer drying kiln:

1.All aluminum alloy shell of the kiln can ensure the resistance to the corrosion.There is glassy rock cotton in the middle of the wall as insulation,which can ensure energy saving effect.

2.Advanced intelligent control system can adjust the technical parameters automatically.So that the veneer materail in the kiln can evaporate efficiently,fast and reasonably in the wet and hot air.It reduces the drying defects during the drying process,improving the veneer drying quality and maintaining the moisture tolerance of the wood fiber.

3.The special wet and hot air flow circulation design ensures veneer drying fast and moisture content equal.

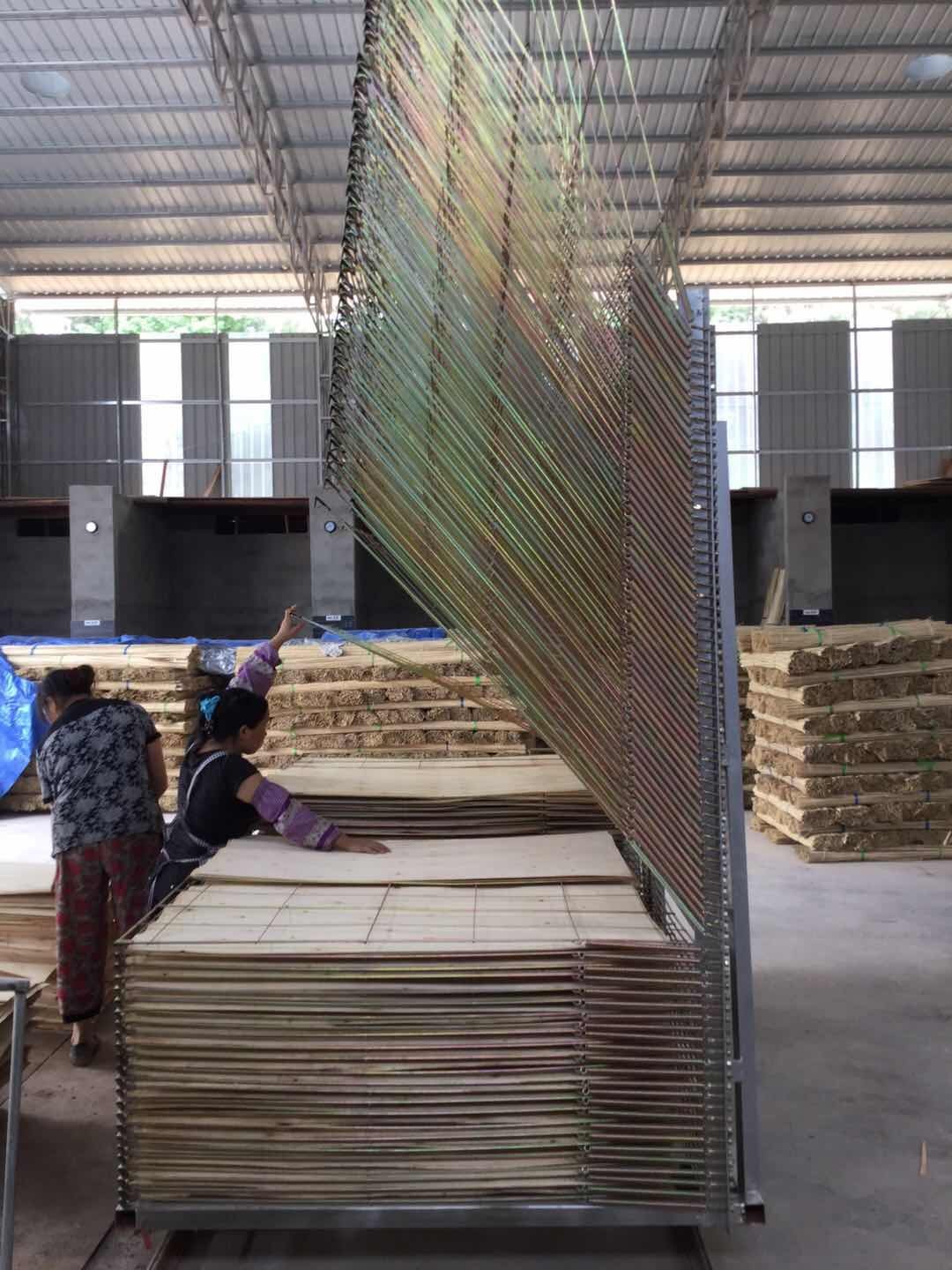

4.Automatic lift platform of the kiln with the louvers can improve the loading speed and reduce the labor costs greatly.Besides,it also seperates the veneer layer,locates,reduces the deformation and improves the drying uniformity.

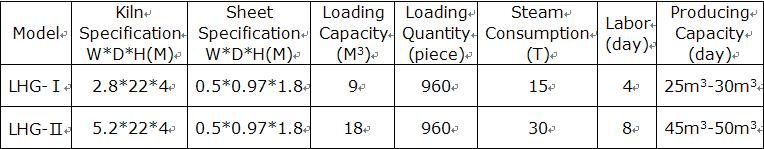

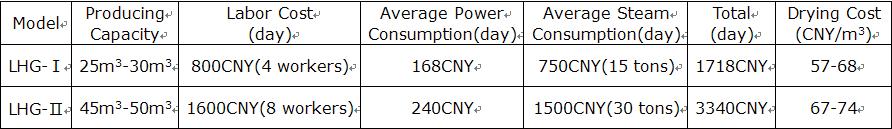

The Technical Parameter of Track Veneer Drying Kiln:

Note:The above data are obtained from the manufacturer.There will be changes because of the different thickness of the sheets.

The Drying Cost Analysis(take the kilns in China for example)

Technical Support

We provide technical support by Phone, Email ,Wechat, WhatsApp and Skype,24 hours online.

We provide English version manual so that kilns operators can learn the tecknology quickly.

Engineer available to service machinery overseas.

Guarantee

The equipment is guaranteed for one year.

1. We provide free spare parts and maintenance service if there is problem with the equipment in one year.

2. You need to pay for the spare parts and necessary maintenance service when there is problem with the equipment after one year.

3. Our company provides necessary wood drying technology and special technical service to meet the requirements of customers.

Patent and Certificate:

Product details:

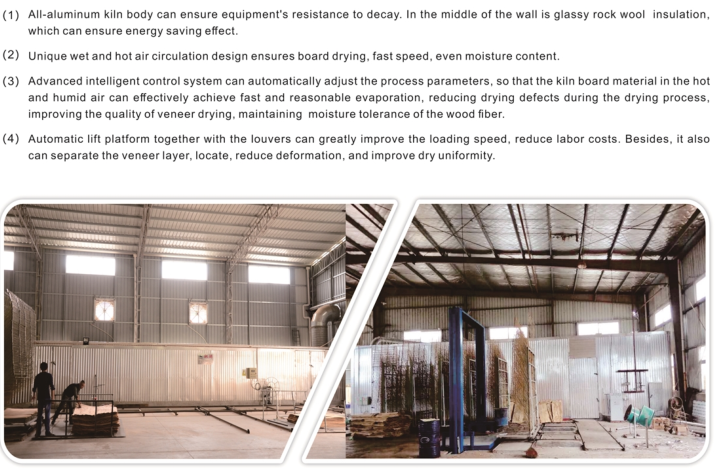

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more