The principle of wood carbonization

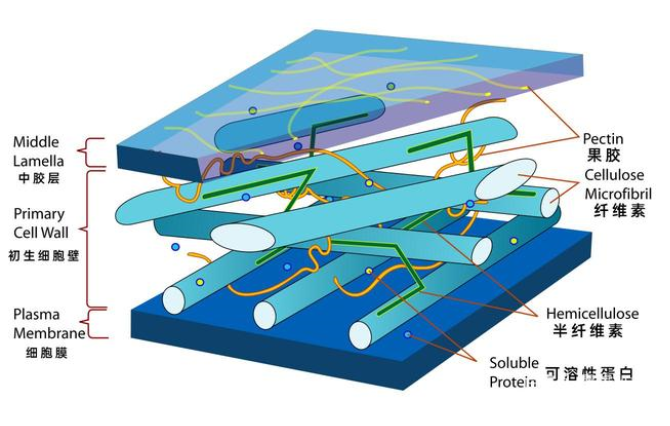

Wood carbonization mainly acts on hemicellulose, cellulose amorphous regions and hydrogen bonds connecting cellulose and hemicellulose.

For example, if we heat wood for several hours to about 175°C, under anaerobic conditions, part of the hemicellulose will degrade, the hydrophilic structure such as hydroxyl groups will decrease, and the stability of wood to humidity will increase; the crystallization ratio will increase, and the dimensional stability and strength of wood will increase; The increase in the lateral connection of the lignin network also enhances the stability and strength of the wood; the formic acid, acetic acid, and phenolic compounds produced in the process can delay decay and prolong the shelf life.

Of course, each manufacturer has its own standard for the specific process flow (temperature and humidity curve), which requires many trials and errors and summarization.

The temperature, humidity and time of heating must be very precise: after the temperature exceeds the vitrification of cellulose and hemicellulose, over time, they are prone to negative situations such as a decrease in strength after a large amount of degradation; similarly, the excessive reduction of hydrogen bonds will also reduce Let the overall strength decrease.

Fujian Zhangping CHIQIN Technology Co. Ltd, is professional in wood drying over 20 years, covering Aluminum Wood Drying Kiln, Heat Pump Wood Drying Kiln without heat source, Veneer Drying Equipment, Wood carbonization kiln,Food Drying Kiln, Kiln Components etc with high quality and reasonable price. Hope to establish business relationship with you!

- Aluminum Wood Drying Kiln

- New Type Steaming Heated Kiln for Wood Dryer

- Hot Water Drying Chamber For Wood Drying Machine

- Heat Transfer Oil Drying Kiln Drying Equipment

- Natural Gas Drying Kiln For Wood Dryer Machine

- Radiata Pine Drying Kiln Drying Chamber For Wood

- Rubber Wood Drying Kiln Timber Drying Chamber

- Rosewood Drying Kiln Channel Kiln For Wood

- Bamboo Drying Kiln Drying Machine

- Intelligent Wood Drying Kiln With Easy Operation

- Heat Pump Drying Kiln

- Heat Pump Wood Drying Kiln Dryer Without Boiler

- Heat Pump Drying Kiln for food

- Veneer Drying Equipment

- Track Veneer Drying Kiln

- Veneer Roller Dryer machine

- 3-layer Net-Belt Veneer Dryer for wood

- Wood carbonization kiln

- High Frequency Vacuum Wood Carbonizating Kiln

- Special kiln for carbonization of bamboo chips