The principle of dehumidification and drying

The basic principle and drying essence of dehumidification drying and conventional drying are the same. Both rely on the convection heat exchange between the hot air in the wood drying room and the wood to be dried, and the air heats the wood and absorbs the moisture evaporated from the wood. The main difference between the two is the method of dehumidifying the air.

During conventional drying, the relative humidity of the drying medium in the drying kiln is reduced by venting moisture to the atmosphere. That is, according to the humidity of the drying process, the conventional drying kiln should regularly discharge a part of the hot air with high humidity from the exhaust duct of the drying chamber, and at the same time inhale the same amount of outside cold air from the suction duct. This method of open air circulation has a large heat loss; dehumidification and drying mainly rely on the principle of air conditioning and refrigeration to condense moisture in the air to reduce the humidity of the air in the drying room, and the air is closed between the drying room and the dehumidifier. , basically no exhaust.

The main components of a dehumidifier are the compressor, evaporator, expansion valve and condenser. The role of the evaporator is like the indoor unit of the air conditioner (or the freezer compartment of the air conditioner). The refrigerant in the evaporator absorbs the heat from the air in the drying room, so that the air is cooled and drained, and the temperature and relative humidity are reduced. The refrigerant in the evaporator changes from liquid to gas due to heat absorption and evaporation, and is boosted by the compressor and then sent to the condenser (also known as the heat exchanger). The condenser acts like a radiator outside the air conditioner (or the radiator on the back of a refrigerator). However, the high-pressure refrigerant in the outdoor radiator of the air conditioner is cooled by the outside atmosphere, making it change from gas to high-pressure liquid, and the heat is dissipated in the air around the outdoor unit. The refrigerant in the condenser of the dehumidifier is cooled by the dry and cold air from the evaporator, and the refrigerant in the condenser releases heat so that the air is heated into hot air and sent back to the drying room to heat the wood. The function of the expansion valve is to reduce the refrigerant liquid from high pressure to low pressure, so that it can re-enter the evaporator to absorb heat and enter the next refrigeration cycle.

When the dehumidifier works, the refrigerant is just a medium for transferring heat. It absorbs the heat of the air at the dehumidifier evaporator and dries the air (reduces humidity), and then releases the previously absorbed in the evaporator at the condenser. The heat (along with the heat energy converted by the compressor's power consumption) warms the air.

Since the dehumidifier recovers the heat released by the air in the drying room, it is an energy-saving drying equipment. Compared with conventional drying, the energy-saving rate of the dehumidifier is 40%~70%.

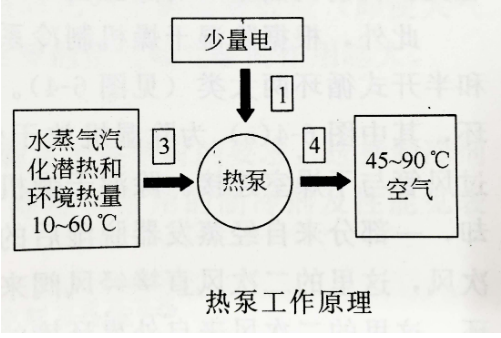

Dehumidification and drying can also be called heat pump drying, which means using a water pump to gather water from a low water level to a high water level. The heat pump relies on the refrigeration working medium to absorb heat at low temperature, and the compressor releases heat at high temperature.

Our main products cover Conventional Wood Drying Kilns,Track Type Veneer Drying Kilns,Heat Pump Drying Kilns,food drying chambers, heat treatment kiln and so on.If you are interested, welcome to contact me.