The main method for determining the moisture content of wood

Production units usually use the gravimetric method and the electrical measurement method.

Gravimetric method: Cut a small piece of test material from wet wood, immediately weigh its weight and record it, and then put the test material in an oven to dry. The temperature of the oven was adjusted to 95-105°C. During the drying process of the test material, its weight was weighed and recorded at regular intervals. The wood is considered to be completely dry until the last two weighed weights are equal or very small. The moisture content of wood can be calculated according to the following formula.

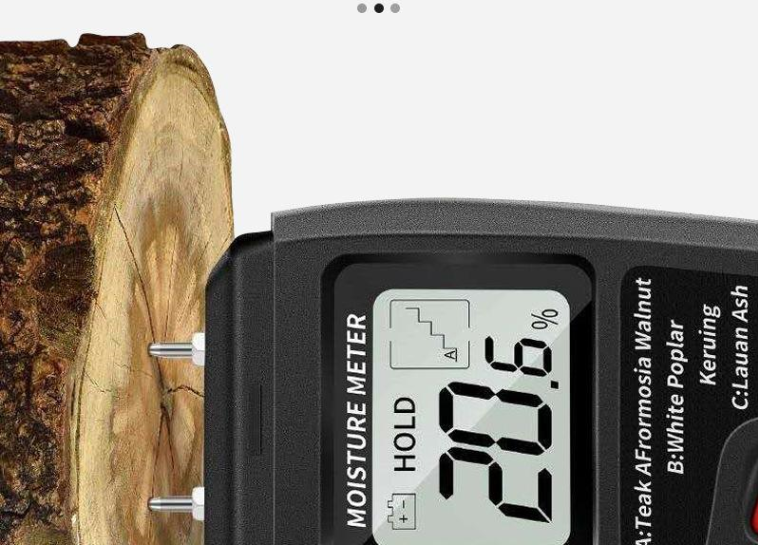

The advantage of using the gravimetric method to calculate the moisture content of wood is that the value is more reliable, but the test material needs to be intercepted from the wood in the whole process, and an oven and weighing equipment are required, and the drying of the test material also takes a certain amount of time.Electrical measurement method: Usually, the moisture content of wood is measured by using a wood moisture content meter. It is made according to the relationship between the electrical conductivity of wood and the moisture content, which belongs to the indirect method to determine the moisture content of wood. Because the dry wood has good insulation, the electrical conductivity of wood varies with the moisture content of the wood. When the moisture content of the wood increases, the electrical conductivity also increases; when the moisture content of the wood decreases, the electrical conductivity also decreases.

When the moisture content of wood is measured by electrical measurement, the measurement accuracy is higher within the range of 28%-5% of wood moisture content, and the measurement error is larger when the measured moisture content exceeds 28%. The moisture content of wood can be measured online in a timely manner using the electrical measurement method. However, due to the high temperature of the wood during the drying process, the measured data is not exactly the same as the actual moisture content of the wood, and needs to be converted.

When using the electrical measuring method to measure the moisture content of wood, the zero point and full scale of the pointer must be calibrated first. If the pointer does not reach the full scale, it means that the battery needs to be replaced or there are other faults.

The advantage of the electrical measurement method is that it is fast and does not need to intercept the test material. However, when measuring wood with high moisture content, the measurement error is large. At the same time, when measuring online, the obtained moisture content must be converted to represent the actual moisture content of the wood.

Our main products cover Conventional Wood Drying Kilns,Track Type Veneer Drying Kilns,Heat Pump Drying Kilns,food drying chambers, heat treatment kiln and so on.If you are interested, welcome to contact me.