Special kiln for carbonization of bamboo chips

- ChiQin

- CHINA

- one month after receving the money

- 30 sets per month

Advantages:

1 The quality of the product has been significantly improved, basically solving the problem of carbon in the bamboo strips.

2 The production process is standardized, standardized and simple to operate.

3. Save more operating costs and labor costs. According to feedback from various manufacturers, the cost is reduced by more than 70%.

4. The specifications of the carbonization kiln can be customized according to customer needs, and micro-pressure or normal pressure equipment can be selected at the same time.

Special kiln for carbonization of bamboo chips

Background technique:

Phyllostachys pubescens is a perennial evergreen tree species, which has the characteristics of fast growth of bamboo stalks and large growth amount. It is an economic crop with long cultivation and wide growing area. It has a very broad application value in industrial applications, especially after the bamboo is processed, it can be made into a variety of products such as furniture, floors, utensils, etc. Multiple advantages.

As a raw material for weaving, carbonization and drying are a very important link in the processing of bamboo products, which can prevent the bamboo from becoming moldy or deformed. Mildew, excessive drying will make the bamboo wood brittle or even cracked, which is not conducive to the reprocessing of the bamboo wood.

Special carbonization kiln for new bamboo chips

The principle of carbonization is to place bamboo chips in a high temperature, high humidity and high pressure environment to decompose and denature organic substances in bamboo materials such as sugar, starch and protein, so that fungi and other insects lose their nutritional sources, and at the same time, insects in bamboo are decomposed and denatured. Eggs, fungi kill. After high temperature and high pressure, the bamboo fiber is coked to become bronze, or similar to brown, and the surface hardness of the carbonized bamboo is also doubled.

Compared with the traditional carbonization process, the new bamboo special carbonization kiln independently developed and produced by our company has the following obvious advantages:

1 The quality of the product has been significantly improved, basically solving the problem of carbon in the bamboo strips.

2 The production process is standardized, standardized and simple to operate.

3. Save more operating costs and labor costs. According to feedback from various manufacturers, the cost is reduced by more than 70%.

4. The specifications of the carbonization kiln can be customized according to customer needs, and micro-pressure or normal pressure equipment can be selected at the same time.

Patent and Certificate:

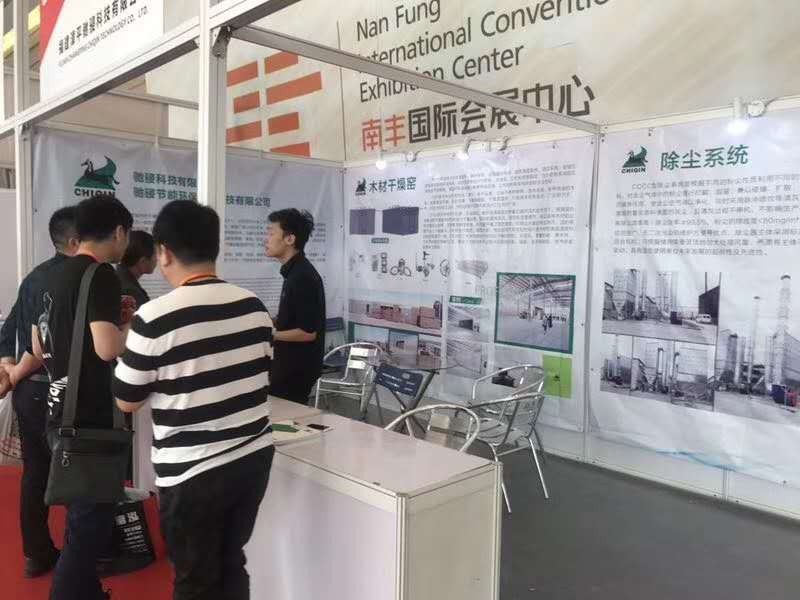

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more