Heat Transfer Oil Drying Kiln Drying Equipment

- Chiqin

- China

- One month after receiving the money

- 30 sets per month

1. Low energy consumption. High thermal efficiency and low power consumption;

2. Less investment. Using wood processing residues as fuel, the drying cost is low;

3. It is convenient to adjust humidity, and the effect of heat and humidity treatment is good. The air circulation is uniform, and the drying quality of the wood is better;

4. Simple operation, easy maintenance;

5. Light weight, movable, mold fast. Easy to install and debug.

Heat Transfer Oil Drying Kiln Drying Equipment

The thermal media of LHJ Series wood drying kiln is heat transfer oil .The wood drying kiln can dry all kinds of timber and all specification of wood.

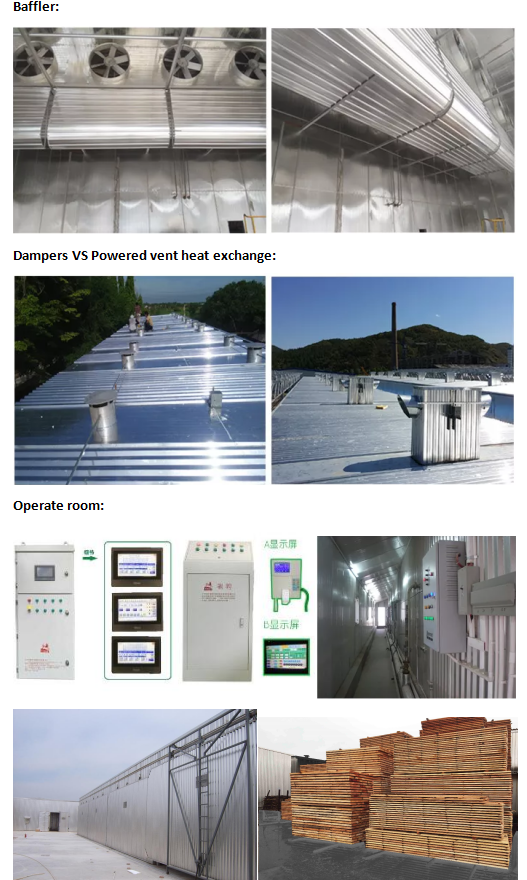

Wood drying kiln is composed of all aluminum alloy case,radiator system,fan circulation system,spraying system,moisture discharging system,automatic control system and wood room.

Our wood drying equipment has been widely used in furniture manufacturing factories and wood flooring factory

Product Description

Maximum drying temperature 110°C

Kiln Housing Stainless Steel or All Aluminum or Masonry

Insulation Fiber Giass 100mm to 200mm

Gate System Sliding lifting kiln door

Control System LIGNOMAT Fully Automatic Control System

Stainless Steel Probes Wirebound and Wireless

Fans Axial Fans 800mm/1200mm,Reversible

Heating Source Hot Water

Related parameters:

|

Type |

wood drying Kiln |

|

Heating Methods |

wood heating ,gas heating ,electricty heating |

|

Power |

10kw-57kw |

|

Shape |

container style |

|

Capacity |

30-200 cubic meter |

|

Heating wood thickness |

5cm-10cm |

|

Certification |

CE/ISO |

|

Weight |

1000kg |

|

Power supply |

220V/380V/415V 3 PHASE 50~60HZ |

This is the main technical parameters of the wood drying kilns available.

Main Features

1, the kiln uses all aluminum plates, beautiful, anti-corrosion, zero loss of thermal energy.

2, no ferrous metal in the kiln, prolong the service life of the kiln, reduce the overall cost, improve the practical efficiency

3, easy to install

4, easy to use, daytime firewood, trim, scrap, scrap, sawdust, shavings can reduce costs, electric heating at night, safe and convenient, but also fully automatic control.

5, concentrated on the many advantages of fuel-wood, electric heating.

6, in order to achieve environmental protection, dust removal devices can be installed according to customer needs, and the smoke can be removed to remove harmful substances to meet emission standards.

7, the amount of loading can be divided into 40 cubic meters, 50 cubic meters, up to 200 cubic meters, can also be designed according to the actual needs of customers for your equipment.

Patent and Certificate:

Cooperation case:

<img title="Wood Drying Kiln" alt="Wood Drying Kiln" src="https://img.waimaoniu.net/1230/1230-202203121446195385.png"/>

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more