Rubber Wood Drying Kiln Timber Drying Chamber

- Chiqin

- China

- One month after receiving the money

- 30 sets per month

Rubber wood belongs to Euphorbiaceae and is the aged wood of rubber trees that produce rubber. Considering the mildew characteristics of rubber wood (usually mildew occurs in 3-4 days), the sawn timber is usually dried and prevented after processing. Mold treatment. After a certain amount of wood drying and anti-corrosion treatment, it can be put into the furniture and building materials market, which is economical and environmentally friendly, so that resources can be used to the maximum.

Rubber Wood Drying Kiln Timber Drying Chamber

Wood kiln drying technology is relatively mature and perfect, and it is more widely used than other drying methods. For a long time in the future, kiln drying will still be the most basic drying method. Conventional kiln drying refers to low temperature kiln drying and normal temperature kiln drying with a drying temperature not exceeding 100 °C. Because the drying temperature is moderate, the humidity can be adjusted. It has little effect on the physical and mechanical properties of wood such as strength and color, and can ensure the drying quality. It is suitable for drying various easy-drying and difficult-drying tree species.

The drying kiln produced by our company adopts the latest and most widely used all-aluminum alloy shell at home and abroad, and a top-air bidirectional reversible periodic forced circulation drying kiln with saturated steam heat or heat transfer oil as the heat source. Features of this product: good thermal insulation performance, corrosion resistance, fast heating rate.

Maximum drying temperature 110°C

Kiln Housing Stainless Steel or All Aluminum or Masonry

Insulation Fiber Giass 100mm to 200mm

Gate System Sliding lifting kiln door

Control System LIGNOMAT Fully Automatic Control System

Stainless Steel Probes Wirebound and Wireless

Fans Axial Fans 800mm/1200mm,Reversible

Heating Source Hot Water

Main Features:

1, the kiln uses all aluminum plates, beautiful, anti-corrosion, zero loss of thermal energy.

2, no ferrous metal in the kiln, prolong the service life of the kiln, reduce the overall cost, improve the practical efficiency.

3, easy to install

4, easy to use, daytime firewood, trim, scrap, scrap, sawdust, shavings can reduce costs, electric heating at night, safe and convenient, but also fully automatic control.

5, concentrated on the many advantages of fuel-wood, electric heating.

6, in order to achieve environmental protection, dust removal devices can be installed according to customer needs, and the smoke can be removed to remove harmful substances to meet emission standards.

7, the amount of loading can be divided into 40 cubic meters, 50 cubic meters, up to 200 cubic meters, can also be designed according to the actual needs of customers for your equipment.

Related parameters:

|

Type |

wood drying Kiln |

|

Heating Methods |

wood heating ,gas heating ,electricty heating |

|

Power |

10kw-57kw |

|

Shape |

container style |

|

Capacity |

30-200 cubic meter |

|

Heating wood thickness |

5cm-10cm |

|

Certification |

CE/ISO |

|

Weight |

1000kg |

|

Power supply |

220V/380V/415V 3 PHASE 50~60HZ |

This is the main technical parameters of the wood drying kilns available:

Kiln Control System

The kiln control system is divided into two types:semi-automatic control system and automatic control system according to the needs of users.They change the temperature and humudity of the kiln by instrument display and control valve.

The temperature is controlled by the change in the amount of vapor sne to the radiator,and the control of humidity is finished by spraying or wetting.The timing reversal of the fan can be achieved by changing the phase sequence of the three-phase power supply of the drag motor.

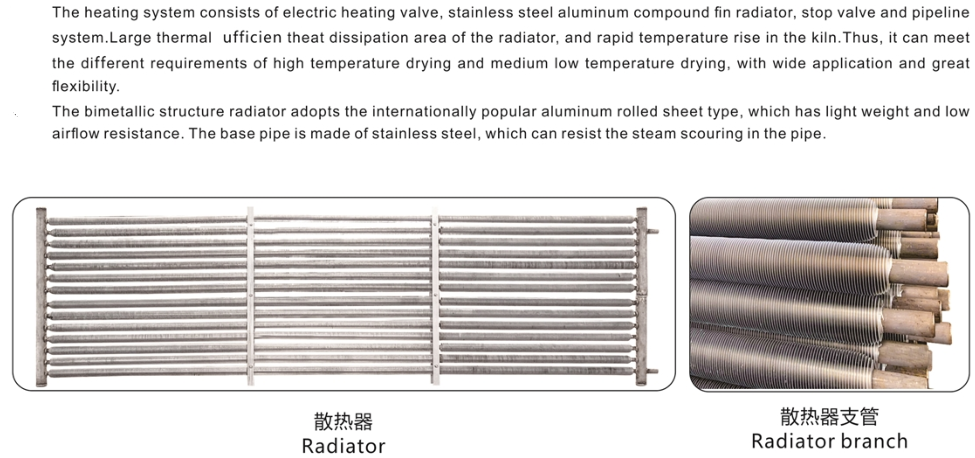

Heating System

The heating system is composed of electromagnetic heating valve.

The heating system can meet different drying requirements from medium-low temperature schedule to medium-high temperature schedule with its strong heating power.

Spray System

The spray system is composed of spraying valve, high-pressure pump, stainless steel spray pipe.

The spray pipe is made by stainless steel so that the carbon steel pipe's drawbacks of heavy corrosion and short service life can be effectively avoided.

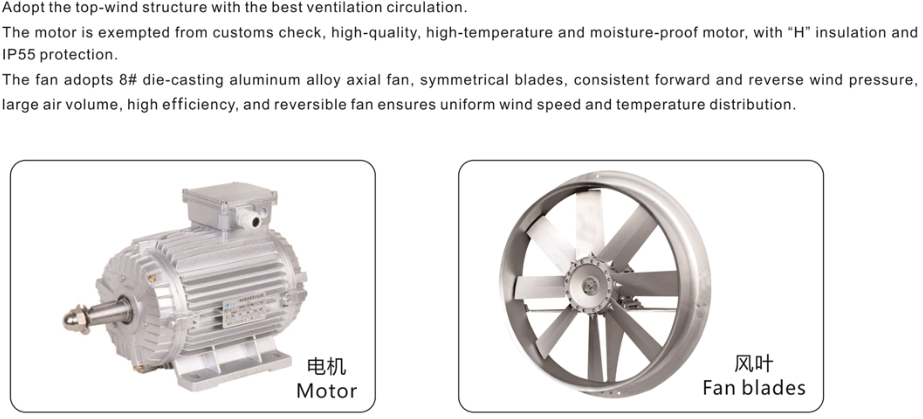

Air Circulating System

The optimum model of kiln is adopted with circulating fans located on the upper side of the kiln. The fan is aluminum molded with big air volume and high efficiency. The electrical power for a single fan is only 3.0Kw so that the energy consuming and the drying cost can be substantially lowered.

Patent and Certificate:

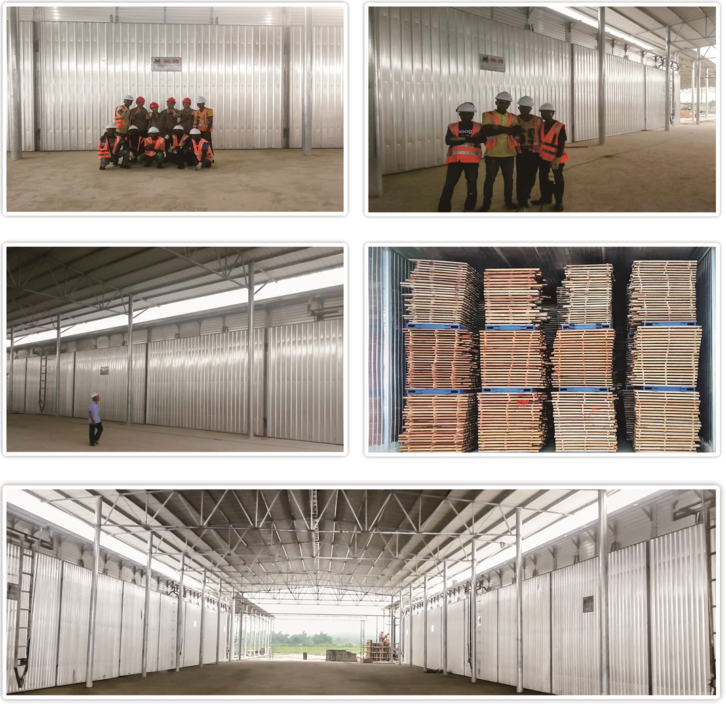

Cooperation Case:

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more