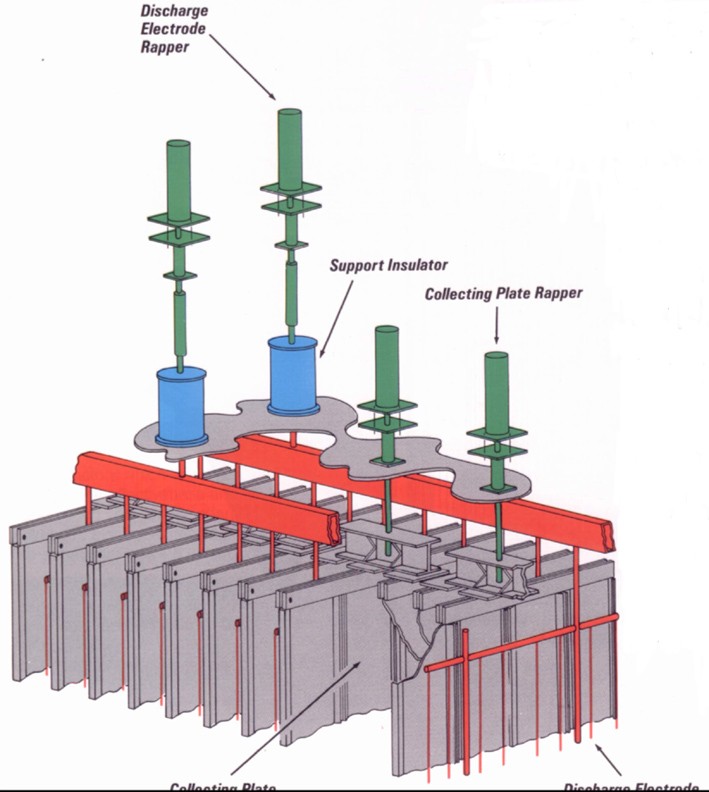

Electrostatic Precipitator Dust Removal Equipment

- CHICHEN

- China

- One month after receiving the money

- 10 sets per month

Fujian Chiqin Technology Co.,Ltd is one of the top high-tech environmental protection enterprises in China. By virtue of its unique power supply technologies characterized by high-energy and high-voltage pulse, and of its own enterprise cultures, Chiqin has become one of the most thriving environmental technology enterprises.

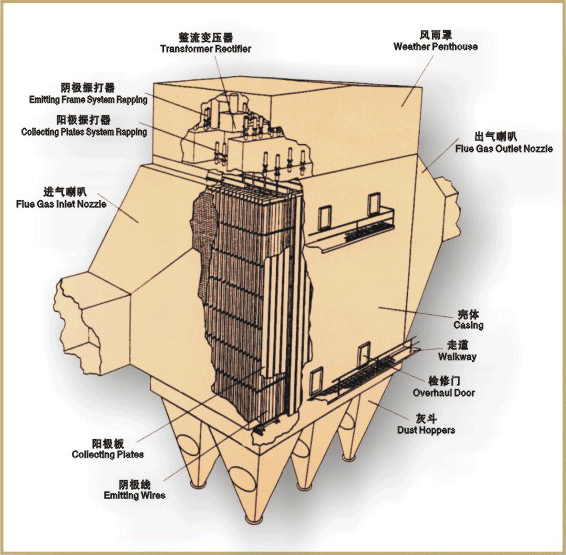

Electrostatic Precipitator Dust Removal Equipment structure

Design considerations and measures

1.Increase section, reduce the flow rate of flue gas flow,improve efficiency of dust removal.

Reducing the electric field wind speed

Extend the residence time

Reduce rapping secondary dust

Reduce wear erosion, extend life expectancy

2.Increase the dust collection area, improve efficiency of dust removal

Adopting the roof electromagnetic hammer rapping

The distribution of force is reasonable: with smaller rapping force, better soot cleaning effect could be achieved

1.The rapping moving parts are placed outside the high temperature dust, resulting in lower failure rate, less maintenance and lower operating cost.

2.The length of each electric field is a meter shorter than other electric precipitator for rapping mode,which is especially beneficial to the renovation of old electric dust remover.

3.The transmission effect and service life of the rapping system are improved by using the cone head insulation shaft of discharge electrode rapper.

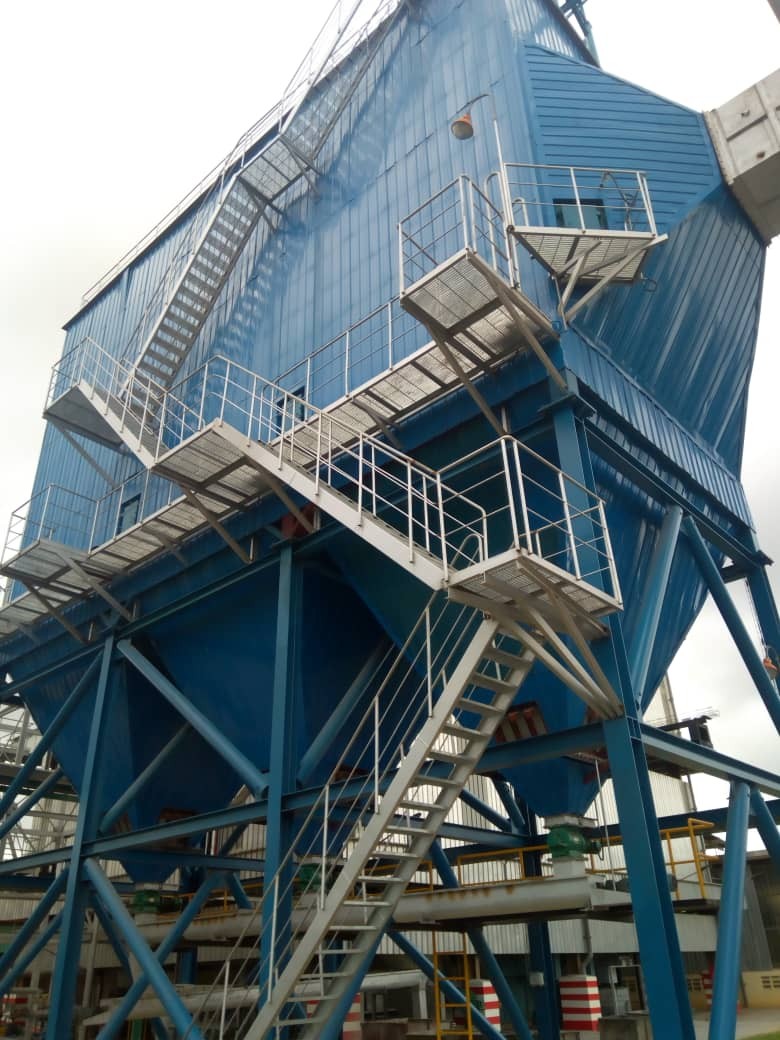

Factory Show

Most commercial timber can be dried as designed, such as as ash, pine, larch, birch, beech, elm, maple, oak or high moisture content wood. Users of wood drying kilns include housing constructions, furniture manufacturers, decking and flooring manufacturers, and other woodworking factories and companies for solid cloth hanger, wood photo frames....more